Weekly Q/A List :

Q1 : Which of the following is not a primary function of the pump casing?

- a. Transmit torque from the driver to the impeller

- b. To convert kinetic energy into pressure energy

- c. To develop dynamic head

- d. Directing flow into and out of impeller

- e. Provide support to the bearing bracket

- f. Incorporate nozzles to connect suction & discharge piping.

Details

Q2 : A pump develops 100 m head while handling kerosene with specific gravity of 0.8. What head will the pump develop if the liquid handled is water:

- a. 120m

- b. 100m

- c. 80m

- d. 60m

Details

Q3 : A pump lifts water from a sump. Static height of the pump center line from the water level in the sump is 5m. Friction loss in the suction pipe line 0.5m, vapor pressure at pumping temperature is 0.5m and the atmospheric pressure is 10.3m of water column. What is the approximate NPSH available at this installation?

- a. 14.3 m

- b. 4.3 m

- c. 4.8 m

- d. 14.8 m

Details

Q4 : Which of the following statements about cavitation is not true?

- a. Cavitation occurs when NPSH available is less than the NPSH required by the pump.

- b. Cavitation is caused by the collapse of air bubbles in the suction side of the pump.

- c. Cavitation does not occur during part flow operation since available NPSH is high.

- d. Cavitation occurs only on the suction side of the impellers.

- e. Cast Iron impellers have the least ability to resist cavitation damage.

Details

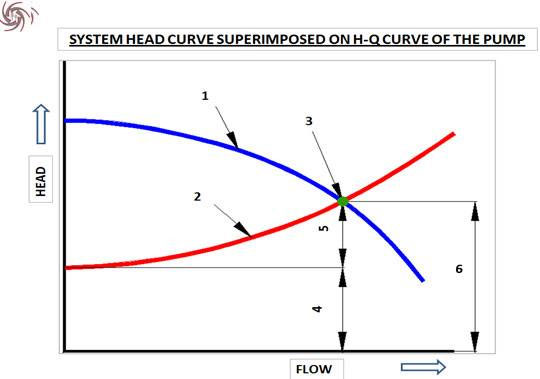

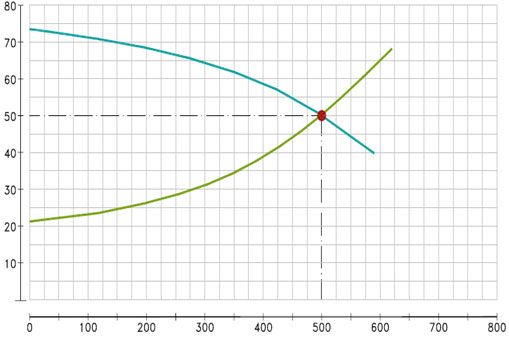

Q5 : The following diagram shows pump performance curve superimposed on system characteristics. Can you identify the various terms in the table?

Description

- a. System Resistance Curve

- b. Friction Head

- c. Static Head

- d. Total Dynamic Head

- e. Head Capacity Curve

- f. Operating Point

- A. (a) - 2 (b) - 5 (c) - 4 (d) - 6 (e) - 1 (f) - 3

- B. (a) - 1 (b) - 4 (c) - 6 (d) - 5 (e) - 2 (f) - 3

- C. (a) - 2 (b) - 6 (c) - 4 (d) - 5 (e) - 1 (f) - 3

- D. (a) - 1 (b) - 4 (c) - 5 (d) - 6 (e) - 2 (f) - 3

Details

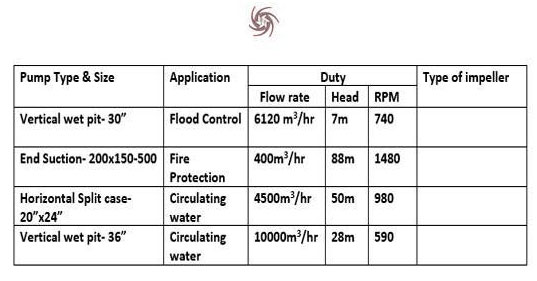

Q6 : For each of the following duties which is the most appropriate type of impeller:

- a. Radial flow

- b. Francis Vane

- c. Mixed Flow

- d. Axial Flow

- 1. c - b - a - d

- 2. a - d - b - c

- 3. d - a - b - c

- 4. b - a - d - c

Details

Q7 : In a pumping system where the major component of the total head is friction, which of the following three methods of flow control is the most energy efficient? The flow through a pump can be controlled by:

- a) Throttling

- b) Connecting or disconnecting pump running in series or parallel

- c) Speed control

Details

Q8 : Which of the following properties are important for selecting the material of construction of an impeller:

- a) Endurance Limit

- b) Corrosion Resistance

- c) Abrasive Wear Resistance

- d) Cavitation Resistance

- e) Casting and machining properties

- f) Tip speed

- g) Cost

- h) Working Pressure

- i) Galling Characteristics

Details

Q9 : According to American Standard NFPA20 for fire pumps, pumps are generally provided with gland packing and mechanical seals are not used. What is the main reason for using gland packing in place of mechanical seals for these pumps?

- a) Gland Packing is easily installed.

- b) Gland Packing is cheaper than mechanical seal.

- c) Leakage tends to increase gradually giving early indication of impending failure.

- d) Gland Packing is less sensitive to the axial movement of shaft compared to mechanical seal.

- e) Gland Packing is easily replaced when the gland is split.

Details

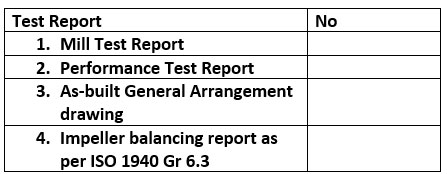

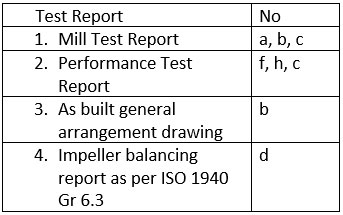

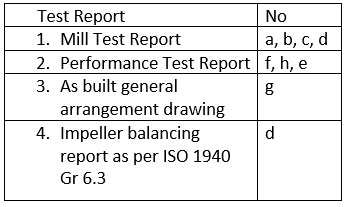

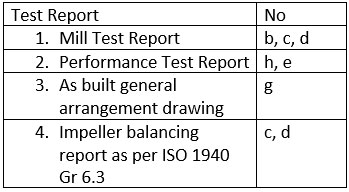

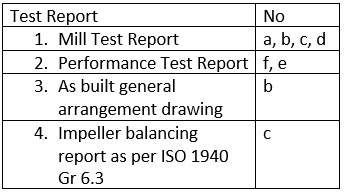

Q10 : The following is a list of some of the Quality Assurance checks carried out by a pump manufacturer:

- a) Shaft Ultrasonic test

- b) Casing UTS, hardness test, chemical test

- c) Impeller - chemical analysis

- d) Impeller – dynamic balancing

- e) Casing - hydrostatic pressure test

- f) Pump - Performance test

- g) Pump - dimensional check

- h) NPSH test

The following is a list of the Test Reports as required by a user:

Please identify the QA document which contains the appropriate test report from the following options:

A.  |

B.  |

C.  |

D.  |

Details

Q11 : Which of the following impeller types has the highest efficiency potential?

- a) Radial flow impeller

- b) Francis Vane impeller

- c) Mixed flow impeller

- d) Axial flow impeller

Details

Q12 : The following are four End Suction ISO 2858 pumps. Pump efficiencies are

- 1. 72%

- 2. 75%

- 3. 81%

- 4. 83%

Can you place the correct efficiencies in the appropriate boxes?

| Pump Size | Best efficiency duty point at 1480 rpm | Efficiency |

|---|---|---|

| A. 125x80-400 | 140 m3/hr, 50m | |

| B. 125x100-400 | 190 m3/hr, 50m | |

| C. 150x125-400 | 300 m3/hr, 50m | |

| D. 200x150-400 | 450 m3/hr, 50m |

- a) A-1 B-2 C-3 D-4

- b) A-4 B-3 C-2 D-1

- c) A-3 B-1 C-2 D-4

- d) A-2 B-4 C-3 D-1

All the pumps generate the same head and impeller diameters are identical (400mm) - Why are the efficiencies different?

Details

Q13 : Select the Pumps for the given duty points:

| S/N | SPEED (RPM) | HEAD (m) | FLOW (Litre Per Sec) |

|---|---|---|---|

| 1 | 1480 | 20 | 100 LPS |

| 2 | 1480 | 22 | 140 LPS |

| 3 | 1000 | 80 | 564 LPS |

| 4 | 1480 | 100 | 564 LPS |

- a) 1: 6HS14 2: 8HS10 3: 16HS32 4: 12HS23

- b) 1: 8HS12 2: 8HS12 3: 14HS32 4: 14HS26

- c) 1: 6HS12 2: 8HS12 3: 16HS32 4: 12HS23

- d) 1: 6HS10 2: 10HS12 3: 18HS25 4: 10HS22

Details

Q14 : You have two pumps conforming to ISO 2858 standard one from Europe (KSB) and the other from Australia (TKL). Both have the same designation - 100x80-315 and both run at 1500 rpm. You would expect both the pumps to have:

- a) Same design capacity, head and impeller diameter

- b) Identical foot-print and installation interface dimensions

- c) Same materials of construction

- d) None of the above

Details

Q15 : American Petroleum Institute Standard API 610 (10th edition) is a process pump standard for petrochemical plants and refineries. A user will insist on pumps complying to this standard when which of the following is required?

- a) Optimum pump efficiency is wanted

- b) Lowest life cycle cost for the installation

- c) Highest reliability in a critical application

- d) Lowest environmental impact

Details

Q16 : A double suction split-case pump is sometimes preferred over an end suction pump because of?

- a) Smaller installation dimensions

- b) Ease of maintenance

- c) Absence of radial thrust load

- d) All of the above

Details

Q17 : There are two identical end suction pumps A and B of designation 200x150-500. Both A and B have identical impellers and shafts, the only difference between these two pumps being that A has a single volute casing while B uses a double volute casing. Which of the following statements is true?

- a) B is likely to be more efficient than A at the best efficiency point (design point)

- b) Shaft deflection at the stuffing box will be higher for B

- c) A will have lower axial thrust load

- d) B will have lower radial thrust load at part flow operation

Details

Q18 : There are two axially split-case pumps with the following description:

| Parameters | Pump model- 6x8-21 | Pump model- 8x10-14 |

|---|---|---|

| Rated capacity | 450 m3/hr. | 750 m3/hr. |

| Rated head | 90 m | 36 m |

| Impeller diameter | 540 mm | 360 mm |

| Impeller width at outlet (including shrouds) | 40 mm | 76 mm |

| Speed | 1480 rpm | 1480 rpm |

| Type of casing | Single volute | Single volute |

| Type of impeller | Double entry | Double entry |

Which of the following statements is true?

- a) Axial thrust of 8x10-14 is likely to be greater than that of 6x8-21

- b) 6x8-21 is likely to be more efficient than 8x10-14

- c) Radial thrust at 50% flow will be more in case of 6x8-21

- d) None of the above

Details

Q19 : Which of the following statement is not true for a two stage axially split-case pump with two back-to-back single-entry impellers?

- a) Protect the shaft from abrasion and wear

- b) Increase the stiffness of the rotating element (shaft to be more precise)

- c) Reduce leakage losses through the stuffing box

- d) None of the above

Details

Q20 : Which of the following statement is not true for a two stage axially split-case pump with two back to back single-entry impellers?

- a) Total head developed by the pump is the sum of heads developed by each stage.

- b) The pump axial thrust is balanced because of two opposed single-entry impellers.

- c) The pump radial thrust is balanced because the volutes of two stages are at 1800 to each other.

- d) The total capacity of the pump is the sum of the flow through each stage.

Details

Q21 : Which of the following statements is not true about packed gland pumps?

- a) Packed gland pumps are preferred over mechanical seal fitted pumps in services such as fire protection where catastrophic failure of mechanical seals cannot be tolerated.

- b) Compared to a mechanical seal fitted pump, mechanical efficiency of a packed gland pump is lower.

- c) It's possible to reduce leakage to zero through a packed gland stuffing box.

- d) Packed gland pumps generally have shaft sleeves to protect the shafts from abrasive wear at the stuffing box.

Details

Q22 : Which of the following statements about pump shaft is not true?

- a) Diameter of the pump shaft depends mainly on the power absorbed (kW), speed of the pump and the permissible shear stress for the shaft material selected.

- b) Shaft stiffness factor (L3/D4) where L is the bearing span and D is the average shaft diameter is one of the measures of the shaft deflection.

- c) Keyways, threads and sharp changes of section are stress raisers in a pump shaft.

- d) A double volute pump needs shaft of larger diameter compared to a single volute pump.

Details

Q23 : Which of the following statements about pump casings is not true?

- a) Pump casing plays an important role in the generation of dynamic head, same as the pump impeller.

- b) Thickness of the pump casing depends on the yield strength of the material used, permissible deflection, corrosion allowance required and the maximum test pressure.

- c) Single volute casing is easier to cast compared to a double volute casing.

- d) Casings are vulnerable to leakage, during pressure test, in areas where there are sharp changes of section.

Details

Q24 : Euler's equation He = U2VU2 / g assumes infinite no of vanes and radial entry into impeller eye (Vu1 = 0). According to this equation, Euler's head depends on which of the following?

- a) Impeller type, speed and outlet diameter.

- b) Impeller outlet vane angle, speed and outlet diameter.

- c) Impeller inlet and outlet diameter, speed and flow.

- d) None of the above.

Details

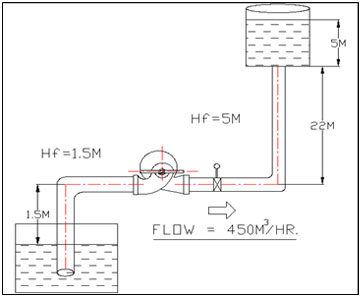

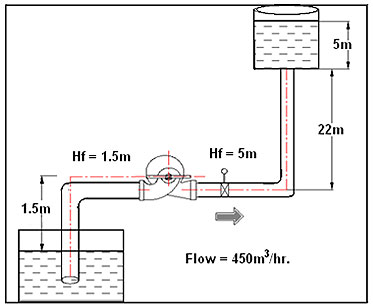

Q25 : For the pumping system shown in the figure below, calculate the total head and the power absorbed by the pump. Assume pump efficiency of 80%.

Power absorbed is given by:

BkW = (Q×H×S.G.) / (3.67×efficiency)

Q – Flow rate in m3/hr

H – Total Dynamic Head in meter water column (m)

S.G – Specific Gravity of the working fluid

- a) 30 m and 46 kW

- b) 32 m and 49 kW

- c) 35 m and 53.6 kW

- d) 30 m and 4.6 kW

Details

Q26 : A centrifugal pump generates a pressure of 100 psi (a head of 231 ft = 100 psi x 2.31), while handling clean water of specific gravity 1.0. What pressures and head will this pump generate when pumping brine with sp. gr. 1.2 and kerosene with sp. gr. 0.8?

- a) Brine (head = 192.5 ft, pressure = 100 psi) & kerosene (head = 288.7 ft, pressure = 100 psi)

- b) Brine (head = 231 ft, pressure = 83.3 psi) & kerosene (head = 231 ft, pressure = 100 ps)

- c) Brine (head = 231 ft, pressure = 120 psi) & kerosene (head = 231 ft, pressure = 80 psi)

- d) Brine (head = 192.5 ft, pressure = 120 psi) & kerosene (head = 208.7 ft, pressure = 80 psi)

Details

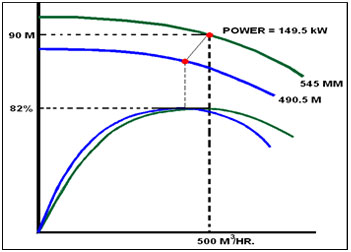

Q27 : The affinity laws of centrifugal pumps suggest that pump capacity varies directly with the impeller diameter, pump head as the square of the diameter and power as the cube of the diameter (assuming the efficiency is unchanged). The law holds good for impeller trims limited by the pump specific speed, impeller type and inlet diameter of the impeller. Assuming that the affinity laws hold good for the impeller trim shown below, what will be the capacity, head and efficiency for the current operating point?

- a) Q = 450 m3/hr., H= 81 m, η = 82% and power = 121 kW

- b) Q = 405 m3/hr., H= 72.9 m, η = 73.8% and power = 109 kW

- c) Q = 450 m3/hr., H= 72.9 m, η = 82% and power = 109 kW

- d) Q = 405 m3/hr., H= 81 m, η = 82% and power = 109 kW

Details

Q28 : A pump manufacturer has to test an external firefighting pump for ship (FiFi pump) of the following specifications:

| Capacity | 2400 m3/hr. |

| Head | 150 m |

| Efficiency | 86% |

| Speed | 1800 rpm |

| Medium | Sea water (sp. gr. = 1.03) |

| Driver | Main propulsion engine through power take-off and gear box |

The manufacturer can test pump at his works, using one of the test motors at six pole speed (1000 rpm synchronous). What will be the rated duty condition of the pump at 1000 rpm at the test bed and what should be the rating of the test- motor. Test bed uses clean cold water (sp. gr. = 1.0) for testing.

- a) Q = 1333 m3/hr., H = 83.3 m, motor = 400 kW, 6 pole

- b) Q = 1333 m3/hr., H = 46.3 m, motor = 230 kW, 6 pole

- c) Q = 740 m3/hr., H = 83.3 m, motor = 215 kW, 6 pole

- d) Q = 740 m3/hr., H = 83.3 m, motor = 215 kW, 6 pole

Details

Q29 : The specific speed of an impeller is expressed as (N√Q) / H^0.75 , where N = speed, Q = flow in USGPM and H = head/stage in ft. Following are four impellers for double suction split-case pumps with their rated duties. What are their specific speeds (US units)?

| Impeller- 5HS12 | Impeller- 6HS17 | Impeller- 6HS22 | Impeller- 8HS26 |

| Q = 1110 US gpm | Q = 1760 US gpm | Q = 2200 US gpm | Q = 3170 US gpm |

| H = 72 ft. | H = 180 ft. | H = 295 ft. | H = 460 ft. |

| N = 1450 rpm | N = 1480 rpm | N = 1480 rpm | N = 1480 rpm |

- a)

Pump A 900 Pump B 975 Pump C 1263 Pump D 1954 - b)

Pump A 975 Pump B 1954 Pump C 1263 Pump D 840 - c)

Pump A 1954 Pump B 1263 Pump C 975 Pump D 840 - d)

Pump A 1263 Pump B 1954 Pump C 975 Pump D 900

Details

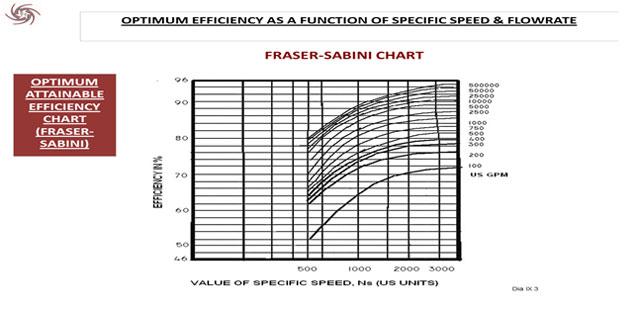

Q30 : Referring to Fraser-Sabini efficiency chart attached, what will be the efficiencies of the four pumps listed?

| Impeller- 5HS12 | Impeller- 6HS17 | Impeller- 6HS22 | Impeller- 8HS26 |

| Q = 1110 US gpm | Q = 1760 US gpm | Q = 2200 US gpm | Q = 3170 US gpm |

| H = 72 ft. | H = 180 ft. | H = 295 ft. | H = 460 ft. |

| N = 1450 rpm | N = 1480 rpm | N = 1480 rpm | N = 1480 rpm |

- a)

Pump A 84% Pump B 81% Pump C 80.5% Pump D 79% - b)

Pump A 83% Pump B 78% Pump C 84% Pump D 80% - c)

Pump A 82% Pump B 84% Pump C 83% Pump D 75% - d)

Pump A 81% Pump B 67% Pump C 85% Pump D 72%

Details

Q31 : Suction specific speed is an indicator of the suction capability of a pump. It is also a measure of suction energy of the pump & its permissible range of operation. External fire pumps for ships (FiFi pumps) operate at a single duty point and the typical duties are as follows:

| Pump A | Pump B | Pump C | Pump D |

| Q = 2400 m3/hr. | Q = 1200 m3/hr. | Q = 600 m3/hr. | Q = 300 m3/hr. |

| H = 150 m | H = 140 m | H = 140 m | H = 140 m |

| N = 1800 rpm | N = 1800 rpm | N = 1800 rpm | N = 2100 rpm |

The suction specific speed (Nss) is given by

(N√Q)

/

((NPSHr)0.75)

where, N = speed in rpm, Q = flow/eye in US gpm and NPSHr is in ft.

Assuming that most commercially designed pumps achieve Nss = 9000 (US units), what would be the expected NPSHr of pumps A, B, C & D if all of them are double suction split-case single

- a)

Pump A 17.2 m Pump B 10.8 m Pump C 6.8 m Pump D 5.3 m - b)

Pump A 10.8 m Pump B 6.8 m Pump C 4.3 m Pump D 3.3 m - c)

Pump A 6.4 m Pump B 4.1 m Pump C 2.5 m Pump D 2.0 m - d)

Pump A 4.3 m Pump B 6.8 m Pump C 10.8 m Pump D 3.3 m

Details

Q32 : A ship-owner is considering installation of two diesel engine driven external fire pumps on the ship deck. Pump duty and suction conditions are as follows: -

Rated capacity of each pump - 600 m3/hr

Rated head - 140 m

Static lift (minimum water level to pump center line) = 3.0 m

Total losses in the pipe line (strainer, bend, straight pipe, etc.) = 0.5 m

Vapor pressure = 0.6 m

Atmospheric pressure = 10.3 m

Available NPSH = (10.3 - 3.0 - 0.5 - 0.6) m = 6.2 m

The ship-owner wants to maintain a safety ratio of 1.2 (NPSHa/NPSHr) to prevent cavitation. What is the maximum speed at which he can run a) an end suction pump b) a double suction pump, considering that pumps operate at B.E.P for rated duties and that they have been designed for Nss = 9000 US units?

- a) End suction-2080 RPM & Double suction - 2080 RPM

- b) End suction-2080 RPM & Double suction - 1470 RPM

- c) End suction-1470 RPM & Double suction - 2080 RPM

- d) End suction-1677 RPM & Double suction - 2370 RPM

Details

Q33 : What is the NPSHa for the following system:

(Given, vapor pressure of water at pumping temperature is 0.5 m & suction vessel is open to atmospheric pressure.)

- a) 6.8 m

- b) 7.8 m

- c) 8.8 m

- d) 9.9 m

Details

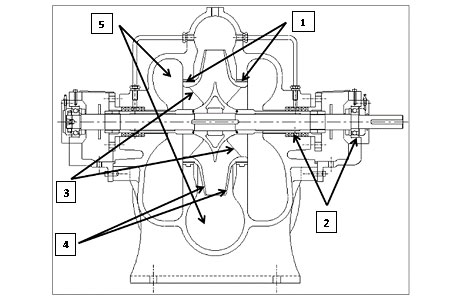

Q34 : The following figure shows various types of losses in a centrifugal pump. Please identify the labels with their positions & select the right option.

| Type of Losses | Labels |

|---|---|

| A) Entrance Shock losses | 1 |

| B) Mechanical losses | 2 |

| C) Leakage loses | 3 |

| D) Disk friction losses | 4 |

| E) Casing hydraulic losses | 5 |

- a)

A 1 B 5 C 2 D 3 E 4 - b)

A 1 B 5 C 3 D 2 E 4 - c)

A 4 B 2 C 1 D 3 E 5 - d)

A 4 B 1 C 5 D 2 E 3

Details

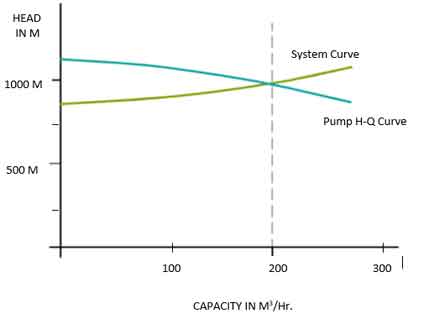

Q35 : Pump H-Q curve has been superimposed on the system curve in the figure below. Identify the head figures.

| Head Figures |

|---|

| A) Static Head |

| B) Friction head at duty point |

| C) Total Head at duty point |

| D) Friction head at 250 M3/Hr. |

| E) Total Head at 750 M3/Hr. |

- a)

A 28M B 22M C 50M D 80M E 9M - b)

A 22M B 28M C 9M D 50M E 80M - c)

A 22M B 28M C 50M D 7M E 85M - d)

A 80M B 28M C 50M D 7M E 22M

Details

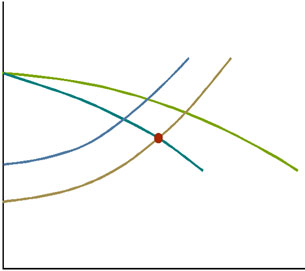

Q36 : The figure below represents curves for a pumping system. One would expect a system curve of this nature in the following systems.

| System | Options |

|---|---|

| Boiler Feed Pump | A) |

| Town Water Distribution | B) |

| Heat Exchanger | C) |

| Mine Dewatering | D) |

Details

Q37 : If the system head is over estimated or if multiple margins are added to arrive at the pump total head, the Pump performance will be sub-optimal. Which of the following statement is not true for such a system?

- a) Pump will discharge more than the rated discharge

- b) Motor may get overloaded

- c) NPSHa may not be sufficient to suppress cavitation

- d) Axial thrust will increase

- e) Radial thrust will increase

Details

Q38 : When the required discharge of a pump is less than the normal discharge (valve fully open) and pump runs at a constant speed, throttling in the discharge line is sometimes adopted to reduce the flow. Throttling is an energy inefficient method of flow control but can be used with pumps using radial flow impellers. What is the main reason why throttling is not recommended for pumps with mixed flow or axial flow impellers?

- a) Excessive radial thrust load at part capacity

- b) Danger of pump operating in the unstable zone of H-Q characteristics

- c) Recirculation & part flow cavitation

- d) Power curve rises towards the shut-off & throttling may overload the motor

- e) All of the above

Details

Q39 : The figure represents two identical pumps working in parallel in a water supply system. Water level in the suction sump varies between high & low limits. Please identify the labels in the diagram & put a tick mark against their right match:

| Item No. & Description of curve | Level |

|---|---|

| 1. H-Q curve of one pump | |

| 2. System characteristics corresponding to highest water level in suction sump | |

| 3. H-Q curve of two pumps running in parallel | |

| 4. System characteristics corresponding to lowest water level in suction sump | |

| 5. Run-out flow when only one pump operate with highest water level in the suction sump |

- a)

A 1 B 3 C 5 D 2 E 4 - b)

A 1 B 5 C 3 D 2 E 4 - c)

A 1 B 3 C 4 D 2 E 5 - d)

A 1 B 3 C 2 D 4 E 5

Details

Q40 : Air entrainment in the suction side of the pump can affect pump performance in diverse ways. Which of the following statements about air entrainment is not true for centrifugal pumps?

- a) Even with small amounts of air in the liquid the performance of the pump declines

- b) Open impellers handle entrained air or gas better than closed impellers due to clearance between the impeller & casing

- c) Air enters the pump suction through vortices formed in the suction sump, release of dissolved gas in the liquid, air leakage through valve stem packing or air deliberately injected into the pump

- d) Entrained air bubbles cushion the destructive effects of collapsing vapor bubbles when the pump is cavitating. Hence, air is sometimes injected deliberately, as a short-term measure, to prevent cavitation damage

- e) Entrained air reduces the NPSH required by the pump and therefore, improves the suction performance of the pump

Details

Q41 : The following is a mixed-up list of advantages of split case (SC) and end suction (ES) pumps. Each option contains some item nos. under the boxes. Please select the right option that correctly segregates the advantages for both the pump types :

- a) Easy inspection without disturbing suction & discharge piping and electric motor.

- b) Light weight & requires less floor space

- c) More sensitive to orientation and geometry of elbows in front of the pump suction

- d) Simpler maintenance, lower maintenance down time

- e) Lower NPSH due to double suction impeller

- f) Only one shaft seal

- g) No chances of volute mismatch between upper & lower cases

- h) No/little axial thrust

- i) High allowable nozzle loads - rigidity of the lower portion of the casing

- j) Higher efficiency, power is not lost in balancing axial thrust

- k) Larger inter-changeability because most pumps conform to international dimension standards for this class of pumps

- l) Lower first cost

- a)

SC ES a b c d e f h g i k j l - b)

SC ES a g b h c i d j e k f l - c)

SC ES a b c f d g e i h k j l - d)

SC ES a c b f d g e i h k j l

Details

Q42 : You have a double volute axially split case pump 14″x16″ in size used for cold well duty of 5000 IGPM (1362 m3/hr.) and 150 ft (45.7 m) at 980 rpm. NPSH required by the pump at 980 rpm is 3.3 m and power absorbed is 200 kW (pump eff. 85%). You want to run the pump at 1480 rpm for a different application and the pump manufacturer has confirmed that the design speed of this pump is 1500 rpm. Please estimate the performance of the pump at 1480 rpm.

| Case A | Case B | Case C |

|---|---|---|

| Q = 1362 m3/hr | Q = 2043 m3/hr | Q = 2043 m3/hr |

| H = 68.6 m | H = 103 m | H = 68.6 m |

| Eff. = 85% | Eff. = 85% | Eff. = 85% |

| Power = 300kW | Power = 674.5kW | Power = 449.3kW |

| NPSHr = 7.5 m | NPSHr = 7.5 m | NPSHr = 3.3 m |

- a) Case A

- b) Case B

- c) Case C

- d) None of the above

Details

Q43 : Following are the typical cost items in a life cycle cost (LCC) analysis of a pumping system. Approximate % costs are presented as a separate list. Please try to match the cost items with your best estimate of percentage figures :

| Cost Heads | Cost Figures |

|---|---|

| 1. Maintenance Cost | a. 10% |

| 2. Operating Cost | b. 40% |

| 3. Downtime Cost | c. 25% |

| 4. Environmental Cost | d. 3% |

| 5. Installation Cost | e. 10% |

| 6. Pump Purchase Cost | f. 7% |

| 7. Energy Cost | g. 5% |

- a)

1 e 2 c 3 d 4 g 5 f 6 a 7 b - b)

1 a 2 c 3 d 4 b 5 e 6 g 7 h - c)

1 a 2 c 3 d 4 b 5 g 6 e 7 f - d)

1 c 2 e 3 d 4 g 5 f 6 a 7 b

Details

Q44 : Losses in a centrifugal pump can be classified, for convenience of analysis, into the following categories :-

- 1) Impeller hydraulic losses

- 2) Mechanical losses

- 3) Leakage losses

- 4) Disk friction losses

- 5) Casing hydraulic losses

The following is a list of locations within the pump. Please match the location with the type of losses.

| Location | Type of Losses |

|---|---|

| A) Impeller shroud faces | 1) Impeller hydraulic losses |

| B) Suction volute | 2) Mechanical losses |

| C) Impeller - wear ring gap | 3) Leakage loses |

| D) Gland Packing | 4) Disk friction losses |

| E) Vane passage | 5) Casing hydraulic losses |

- a)

A 1 B 3 C 5 D 2 E 4 - b)

A 1 B 5 C 3 D 2 E 4 - c)

A 4 B 5 C 3 D 2 E 1 - d)

A 4 B 1 C 5 D 2 E 3

Details

Q45 : The method followed in the field for a quick estimation of the minimum flow through the pump, to limit temperature rise to 80C (150F), is to calculate the power at B.E.P and consider 10% of the power (HP) in US gpm as the minimum flow (thermal) through the pump. For example, if the power absorbed is 100 HP (75 kW), the minimum flow will be estimated as 10 US gpm (2.3 m3/hr)

A multi-stage ring section pump is being used for the following duty :-

| Capacity | 108 m3/hr |

| Head | 500 m |

| Speed | 2950 rpm |

| Temperature | 900c |

| Specific gravity | 0.956 |

| Medium | De-mineralized water |

| Pump Efficiency | 72 % |

The user needs to plan for a minimum flow recirculation arrangement to prevent temperature rise beyond 80C. As a first approximation, what minimum flow should be considered for the recirculation arrangement?

- a) 19.5 m3/hr

- b) 6.0 m3/hr

- c) 10.8 m3/hr

- d) 4.4 m3/hr

Details

Q46 : For API 610 process pumps, the governing design philosophy is a very high level of mechanical reliability. This requires adopting design features which can lead to sub-optimal pump efficiency. The following is a list of special design features of API process pumps. Please identify one feature that definitely does not compromise pump efficiency.

The user needs to plan for a minimum flow recirculation arrangement to prevent temperature rise beyond 80C. As a first approximation, what minimum flow should be considered for the recirculation arrangement?

- a) Double volute casing construction

- b) Large shaft to reduce shaft deflection

- c) Wear ring clearances as per API standards

- d) Large mechanical seals

- e) Centre-line mounted casing

Details

Q47 : Disk friction drag is a major component of pump losses in low specific speed pumps. The following are the duties of five split-case pumps - all pumps are single stage with double suction impellers. Pump D uses a double volute casing while all others have single volute casings :

| Pump A - 8x8-12 | Pump B - 6x8-14 | Pump C - 6x8-17 | Pump D - 6x8-21 |

| Q = 450 m3/hr | Q = 450 m3/hr | Q = 450 m3/hr | Q = 450 m3/hr |

| H = 22 m | H = 32 m | H = 55 m | H = 90 m |

| N = 1460 rpm | N = 1480 rpm | N = 1480 rpm | N = 1480 rpm |

Which pump is likely to have the highest disk friction loss as a proportion of the power input?

- a) A

- b) B

- c) C

- d) D

Details

Q48 : Leakage loss in a single stage centrifugal pump with shrouded impeller takes place through the clearances between the impeller and casing wear rings. Leakage loss is a function of the pump specific speed. Lower efficiency of low specific speed centrifugal pumps is due, mainly, to high leakage and disk friction losses. Which of the following statements regarding leakage losses is definitely not true?

- a) Drop in efficiency due to increased leakage losses can be corrected by restoring wear ring clearances

- b) Use of compatible impeller and wear ring materials with adequate anti-galling properties allow smaller wear ring clearances and reduce leakage losses

- c) Leakage loss depends on the pressure differential between the suction & delivery side of wear ring and on wear ring clearance. Width of the wear ring does not have any effect on the leakage losses

- d) Increased shaft stiffness reduces the shaft deflection at the impeller and allows lower clearance between impeller & wear ring and this reduces leakage losses

Details

Q49 : Power balance diagram and specific speed vs. efficiency charts suggest that for a required combination of capacity and head, a pump of optimum efficiency can be obtained if the operating speed is selected such that the pump specific speed is close to 2500 US units. It is to be noted that suction condition (NPSHa, limiting suction specific speed, etc.) often determine the pump operating speed & does not allow using the optimum specific speed of 2500 US units mentioned above. A refinery is considering installation of cooling water pumps of the following description :-

| Type | Vertical shaft axially split-case |

| Capacity | 2200 m3/hr |

| Head | 35 m |

| Suction | 3.0 m positive head on the suction side |

| Supply System | 50 Hz |

The refinery can choose from operating speeds of 3000 rpm, 1500 rpm, 1000 rpm or 750 rpm. Which operating speed is likely to offer the optimum pump suction performance with efficiency?

- a) 1500 RPM

- b) 1000 RPM

- c) 750 RPM

- d) 3000 RPM

Details

Q50 : Lower the specific speed of the pump, higher is the ratio of impeller outlet diameters (D2) to impeller inlet or eye diameter (D1). Lower the D2/D1 ratio, lower is the allowable range of operation to prevent recirculation, low flow cavitation, vibration & radial loading. Out of the three options listed below which pump will permit the widest range of head-capacity operation.

| Pump A | Pump B | Pump C |

|---|---|---|

| Q = 2200 m3/hr | Q = 2200 m3/hr | Q = 2200 m3/hr |

| H = 35 m | H = 35 m | H = 35 m |

| N = 1480 rpm | N = 980 rpm | N = 740 rpm |

| Type - Axially split-case | Type - Axially split-case | Type - Axially split-case |

- a) Pump A

- b) Pump B

- c) Pump C

- d) Insufficient data