Specification Sheet

The fire pumpset supplied by Pumpsense shall include the pump, driver, controller and fittings as detailed in the following technical specifications. All the materials supplied shall be installed as recommended in NFPA 20.

Pump Technical Details:

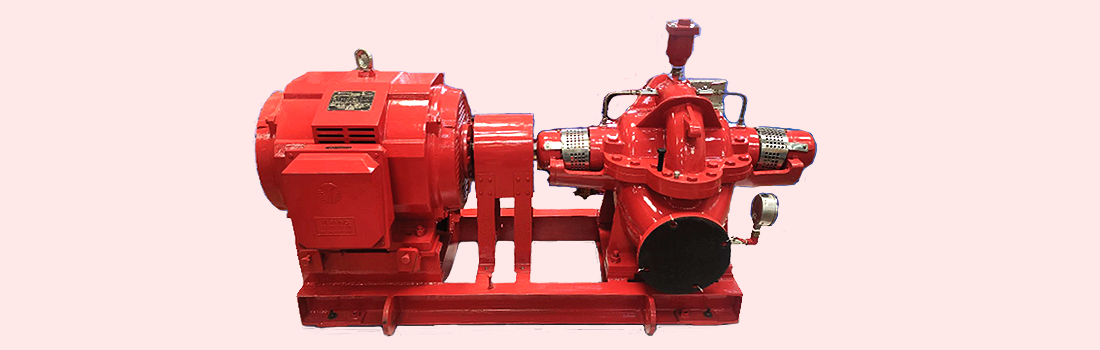

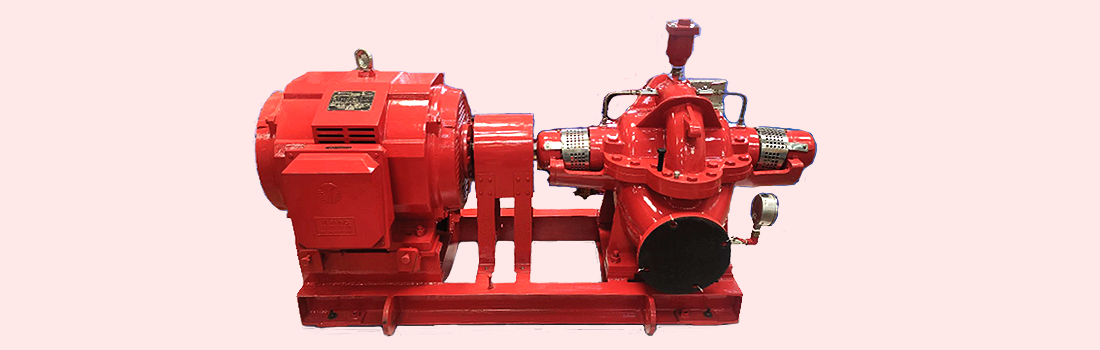

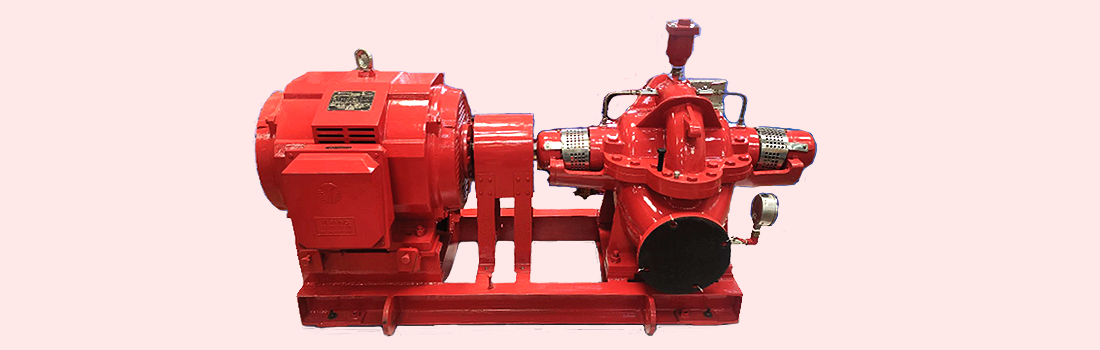

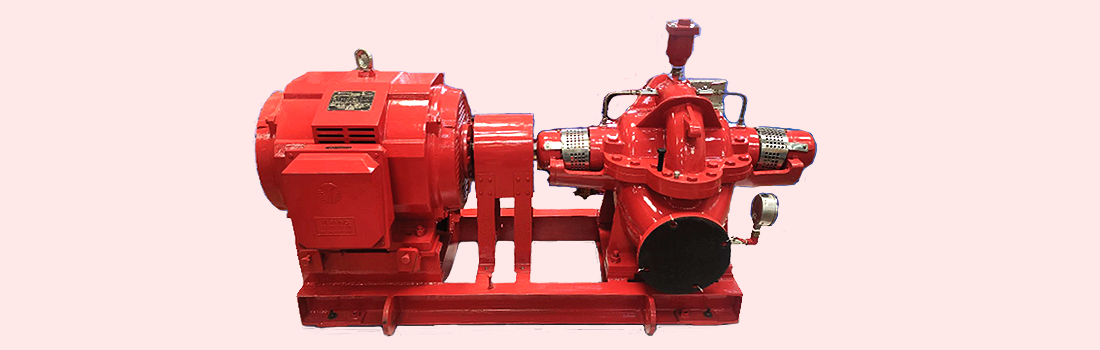

The UL/FM certified fire pumps will be horizontal, centrifugal single/multi stage axial split case type or centrifugal single stage end suction type with constructed specifically for fire pump services by Pumpsense. The pump must be selected for the certified duty ……… USgpm and the differential head ….. psig within the listed range for the specific duty and speed. The pump must deliver 150% of the rated flow and the head ratio with the rated heat should not be less than the 65% whereas the rated head should not be more than 140% of the pump shut-off head for the specified impeller. The pump should draw the water from the aboveground tank (or any other sources with positive pressure) with a maximum pressure ….. psig or from underground tank with a minimum pressure …. Psig. For clear water usage, Pump casings are in CI FG260, impeller in bronze LG2, shaft 410 and all other rotating elements in standard bronze construction. Bearings are mainly grease lubricated. Special materials are on request for sour fluid using for firefighting application.

Electric Motor:

For UL or UL and FM certified pump sets, the electric Pump should be coupled by a flexible pin and bush type coupling with UL listed rating …. HP, ODP/TEFC, maximum ambient temperature …….. deg.C, supply frequency ….. Hz, supply voltage ……. V, ….. Phase, …. Efficiency class horizontal foot mounted motor.

Electric Fire Pump Controller:

The fire pump controller shall be factory assembled, wired and tested as a unit prior to shipment. The controller shall be available for 380-415 Volt, 50 Hz or 440-460V three phase power. The controller shall include the following standard features:

Diesel Engine:

For UL/FM certified diesel pump set, the engine should be UL and FM certified horizontal 4 stroke internal combustion engine, have FM 1311 approved heat exchanger cooling loop, UL listed driveshaft (only for UL listed set; for only FM approved set non-UL driveshaft is accepted). The location of the engine installation is at ………..mm from sea level with an ambient temperature ……….. deg.C. Stator voltage ….. (12/24) V DC, Jacket Water Heater Voltage ….. (120/240) V AC and type of silence ………… (Industrial/Residential).Engine rating will be …… HP with a derating factor for the temperature and altitude.

Diesel Fire Pump Controller:

The fire pump controller shall be factory assembled, wired and tested as a unit prior to shipment. The controller shall be available for either 12VDC or 24VDC systems. The controller shall include the following standard features:

- NEMA type 2 drip proof metal wall mount or freestanding enclosure. Optional enclosure types are available on request.

- Dual solid state battery chargers

- Two outer door mounted crank push buttons and two inner panel mounted battery on/off switches

- Outer door mounted key operated AUTO, OFF, MANUAL, mode selector switch

- The controller shall be supplied with a solid state pressure transducer with a range of _______ psi for monitoring system pressure and providing the feedback to the controller

- Touch screen pushbuttons shall be provided on HMI for easy screen navigation, alarm reset, and alarm silencing

- Controller settings shall be programmable through the HMI and shall be protected by passwords

- The system status data shall be displayed on the HMI

- Audible alarm shall be provided with alarm silence feature for silence able alarms

- Data logging shall be possible with real time/date clock to store the continuous pressure log, event log, alarm log and all user changeable set points and system data. Battery backup of any kind shall not be allowed

- The controller shall be provided with a USB port capable of accepting USB flash memory disk to download historical data of events, alarms and pressure logs

- Anti-condensation space heaters and other options can be offered on request.

Standard Accessories for Pump Set:

- The horizontal axial split case pump should be equipped with an automatic air release valve with …..mm inlet size either UL listed or UL and FM certified. For end suction pump no need of an automatic air release valve.

- The horizontal axial split case pump and end suction pump driven by an electric motor should have a casing relief valve with …. mm inlet size either ……. (angle/globe) configuration with a pressure range rating …… psig. The valve should be set at sight below the pressure of the pump shut-off pressure to protect the pump from the overheating.

- Compound Suction Gauge, 3-1/2” dial with ¼” BSP port and isolation valve.

- Discharge Gauge, 3-1/2” dial with ¼” BSP port and isolation valve. Discharge gauge is either UL listed or UL and FM certified.

- The pump/motor set or pump/engine set will be mounted on a base frame. Base frame should be machined properly having the lifting points for the loading and unloading purpose. The base frame should have provision of the heavy duty anchor bolts to fit on the foundation.

- Diesel engine set pump will be supplied with UL FM or UL certified main relief valve as per the minimum size mentioned in the NFPA20 for the specific pump duty. Main relief valve will be …….. (flanged/grooved) type, pressure rating …….. psi, ……. (angle/globe) orientation.

- Orifice type flow meter FM approved minimum size ……. Inch as per NFPA20, …….. (flanged/grooved) type.

- Each diesel engine should have an independent fuel tank. Fuel tank size will be 1gallon for 1HP with 5% volume for expansion and 5% for residual volume. Fuel Tank will be supplied with minimum accessories as per NFPA20, 2inch lockable fuel fill cap, 1inch drain port, mechanical direct fuel gauge, emergency vent port, port for low level fuel level switch. Diesel Tank can be single wall or double wall. Double wall diesel tank should have a 2” port at the outer containment to detect the leakage in the inner containment. There should be fuel inlet line port and return line port in the fuel tank to be connected with the diesel engine.

Jockey Pump:

The jockey pump shall be a vertical multistage inline pump with a capacity ………. USgpm, …….. psi differential head. The jockey pump will be driven by a TEFC motor …. HP rating, Voltage ….. V, Frequency …. Hz, Phase ….., Speed … rpm.

Jockey Pump Controller:

The jockey pump controller shall be factory assembled, wired and tested as a unit prior to shipment. The controller shall include the following standard features:

- NEMA type 2 drip proof metal wall mount enclosure. Optional enclosure types are available on request.

- The controller shall have a fused horse power rated door interlocked rotary switch

- The controller shall be of combined manual and automatic type designed for one of the following starting methods : (a) DOL (b) Star/Delta

- The controller shall provide protection against overload and single phasing

- The controller shall be supplied with a solid state pressure transducer with a range of _______ psi for monitoring system pressure and providing the feedback to the controller

- Touch screen color Human Interface Device (HMI) display shall be provided of minimum 3 inch size capable of being read in both direct sunlight and dark lighting conditions

- Touch screen pushbuttons shall be provided on HMI for easy screen navigation, alarm reset, and alarm silencing

- Controller settings shall be programmable through the HMI and shall be protected by passwords

- All features shall be enabled or disabled through the HMI, no jumpers or external wires shall be needed or allowed to activate or deactivate a feature

- The system status data shall be displayed on the HMI

- The controller shall be provided with a USB port capable of accepting USB flash memory disk to download historical data of events, alarms and pressure logs