PUMPSENSE FLUID ENGINEERING PVT LTD

PUMPSENSE FLUID ENGINEERING PVT LTDPUMPSENSE FLUID ENGINEERING PRIVATE LIMITED |

GENERAL QUALITY PLAN

|

CUSTOMER : IMAGINE FLUID ENGINEERING PVT LTD |

||||||||||||

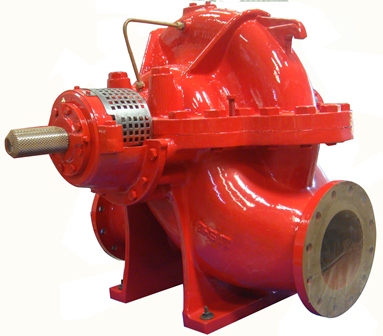

| Reference no | Product Description | Centrifugal Pumps | Order No | |||||||||||

| Sl No | Components & Operation | Characteristics | Classi-fication | Type of Check | Quantum of Check | Reference Documents | Acceptance Norm | Form of Record | Inspection Agency | Remarks | ||||

| 1 | MATERIAL CONTROL | |||||||||||||

| 1.1 | Casing : Top Half, Bottom Half | Physical & Chemical Properties,Dimensions | CR | UTS Hardness | 1/heat/batch | DIGGG50 |

Lab Report | 3 | 2 | 1 | Pouring witnessed by PSF

|

|||

| 1.2 | Impellers | Chemical Properties | CR | Chemical Analysis | 1/heat/batch | DIGGG50 |

Lab Report | 3 | 2 | 1 | Pouring witnessed by PSF | |||

| 1.3 | Shaft | Physical & Chemical Properties,Dimensions,Sub-Surface defects | CR | Physical Properties & Chemical analysis, measurement, ultrasonic test | 1/Bar 100% |

ISO 1940 Gr 6.3Manuf. Drawing | AISI410 Manuf. Drawing | Mill T.C or lab Report |

3 | 2 | 1 | Identificationby PSFof test bars for chemical analysis Physical propertieswill be provided at the time of identification | ||

| 2 | IN PROCESS CONTROL | |||||||||||||

| 2.1 | All components under 1.0 | Visual Defects, Dimensions | MA | Visual Exam, Measurement | 100% | Manufacturing Drawings | Manufacturing Drawings No harmful defects | Inspection Report | 2 | - | - | |||

| 2.2 | Casing | Leak tightness | CR | Hyro Test (duration min.30 minimum) | 100% | Technical Specification, Data Sheet | No Leakage | Inspection Report Hydraulic Institute standards | 2 | 1 | - | Hydrostatic Pressure Test (22kg /cm2) | ||

| 2.3 | Impellers | Static, Dynamic, Residual Unbalance | CR | Static & Dynamic Balancing | 100% | ISO 1940 | ISO 1940 Gr 6.3 | Inspection Report | 3 | 2 | 1 | |||

| 3 | SUB - ASSEMBLY CONTROL | |||||||||||||

| 3.1 | Rotor Assembly | Eccentricity | MA | Measurement | 100% | Manufacturing Drawings | Inspection Report | 2 | - | - | ||||

| 3.2 | Complete Pump Assembly | Completeness, Correctness, Cleanliness, Clearance, Freeness, Alignment | MA | Visual Exam. Measurement | 100% | Approved drgs. & Mfg. standards. | Inspection Report / Ckeck Lists | 2 | - | 1 | ||||

| 4 | FINAL INSPECTION, TEATS PACKING - DESPATCH CONTROL | |||||||||||||

| 4.1 | Pump (with test motor) | Test for pumps only - Q vs Efficiency, Q vs Head, Q vs Power | CR | Performance Test at reduced speed | 100% | Technical Specification, approved data sheet approved curves - ISO2548 | Technical Specification, Data sheet, ISO2548, Class C | Performance Test Record Plotted Curves | 2 | 1 | - | Minimum 6 points covering the range of head / Capacity. Acceptance norms as per ISO9906 Class1 | ||

| 4.2 | Stripdown after performnce test | Undue Wear, Tear & Breakage. | CR | Visual exam after stripping | 1/Type/Size | Technical Specification | Inspection Report | - | - | - | ||||

| 4.3 | Completion of all stages | Completion | MA | Verification of inspection report , TC | 100% | Approved Manufacturing Drawings Technical Specification | Inspection Report | - | - | - | ||||

| 4.4 | Painting & Packing | Surface Finish, Soundness of packing, Marking, etc. | M1 | Visual Exam, measurement | 100% | Approved Procedure, Pumpsense check list | Inspection Report, Manufacturer's check list | 2 | - | - | ||||

|

Classification CR - Critical MA - Major Inspection P - Performance W - Witnessed by R - Reviewed by |

Note 1 : Material identification marks for all parts shall be maintained upto the time of final assembly acceptance 2 : Separate test bars as per standard would be cast, from the same ladle material as that used for making castings, which shall be identified by Pumpsense 3 : Physical testing shall be witnessed from sample drawn by Pumpsense. Chemical test sample will be drawn by Pumpsense but testing shall not be witnessed by Pumpsense |

The agencies are codified as 1,2, & 3 where - 1 - stands for purchase or third party 2 - Stands for vendor ( Pumpsense) 3 - Stands for sub-vrndor of Pumpsense |

|||||||||||

| Issue No : | Revision No : | Issued By: | Approved By: | >>Back | ||||||||||