Business Objectives

Pumpsense will create and deliver a range of centrifugal pumps & technical / business advisory services to the users and makers of centrifugal pumps. While the products will strive to be the best in their class, the services will help the pump users to select the right pump with optimum energy consumption and service life and will also help them get the best performance from their existing pumping installations. The services for pump makers are aimed at helping them create greater customer value and increased customer satisfaction.

Pumpsense will work closely with its customers to constantly innovate and improve its service offering. It will provide an open learning environment to its employees and associates where high ethical standards and mutual support lead to a fulfilling and enriching life experience

Background

Pumpsense has been promoted by Himadri ( himadri.sen@worldofpumps.com ) and Nandita Sen with the support of their associates in the pump community. Pumpsense is based on the learning and experience accrued from establishing and running a successful pump manufacturing company, Allied Centrifugal Pumps Pvt Ltd, (ACP), since 1995. This company successfully developed split-case, end-suction and inline pumps for industrial, building services and marine applications. In addition, it offered design and development services to international pump companies for listed fire pumps, both split-case and inline, and a range of large end-suction pumps for the European market. The company merged with WILO SE of Germany in 2005. In 2008, the company produced nearly a 1000 split-case and end-suction pumps and achieved a turnover of US$ 6.0 million with an outstanding bottom line.

Himadri and Nandita Sen handed over the management of ACP to Mather+Platt (A WILO Group Company) in May 2009 in order to start PUMPSENSE, a company dedicated to creating innovative products & services for centrifugal pump users and manufacturers.

|

Product Overview |

|

|

|

|

| |

|

|

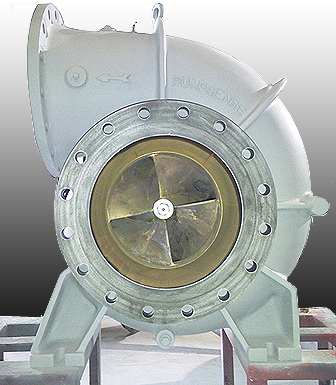

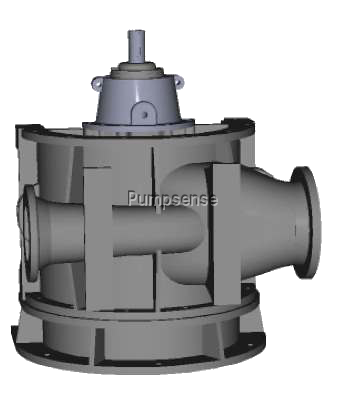

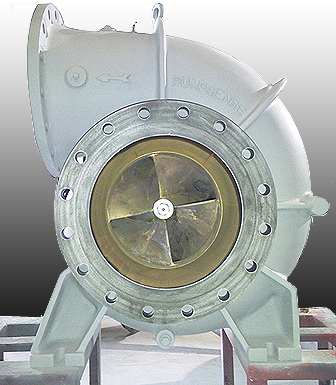

The first pump in our new EMF range has been developed for an

Australian customer.

This range has a total of four mixed flow pumps- 8", 10", 12" & 16" discharge. This picture shows pump model EMF 400-384 built for a rated capacity of 1600 m3hr@10.9m head, 970 rpm. |

| |

|

|

|

|

|

| Centrifugal Pumps Training |

| Pump Design

Key aspects of hydraulic & mechanical design of centrifugal pumps

|

| Pump Selection

Optimum selection based on capacity, head, available NPSH, fluid handled etc.

|

| Pump Operation

Ideal pump specification to ensure optimum hydraulic & mechanical performance & reliability |

| Pump Performance

Performance characteristics of pumps and pumping systems. Also method of controlling flow and energy implications |

| Energy optimisation

Optimum selection of pump and system elements in pumping systems |

|

|

|

| |

|

|

|

|

| QCDD Approval - Our UL listed fire pumps 4HF12, 4HF12L, 4HF13, 5HF11, 6HF14K, 6HF12, 8HF13, 8HF20 have received QCDD (Qatar Civil Defense Department) Approval. This approval is in compliance with UL 448 & NFPA 20. We can now supply fire-safety equipment associated with civil defense works to Qatar. |

|

| Pumpsense 2020 - New Production Facility- We are very happy to announce that we have completed the building of a new 22,000 sq. ft. production facility located in Vivekanda Industrial Estate, Howrah & moved our operations to this new location. This facility now allows us to handle much larger product sizes for manufacturing & testing, alike. A better transport access & higher production capacity will now let us to meet the demands of a growing market. We look forward to continued support from our valued customers in our new ventures. |

|

| Pump test bed design and engineering - We have now completed three test bed assignments - Fire pump test set up for an international pump maker in Goa, India; Vertical wet pit & horizontal pump test set up for a large engineering company in Ipoh, Malaysia and a submersible pump test set up in Australia. |

|

| Special Purpose Axially Split Case Pump - Three stage split case pump has been specially designed for condensate extraction duty. Double suction first stage with two single suction impellers on either side of it characterises thislow NPSH pump |

|

|

PUMPSENSE FLUID ENGINEERING PVT LTD

PUMPSENSE FLUID ENGINEERING PVT LTD