PUMPSENSE FLUID ENGINEERING PVT LTD

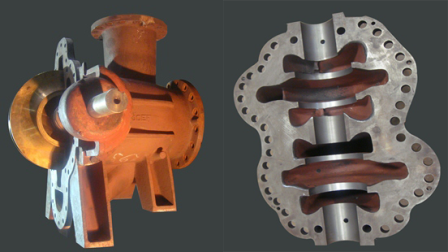

PUMPSENSE FLUID ENGINEERING PVT LTD Engineering Machined Components for Pumps is a Specialised Process |

|

|

At Pumpsense,we have developed this technology to a

precise science. And in the process, established an exclusive

cell to engineer machined pump components. This cell not only

has access to all the manufacturing facilities and technical

skills, but also has a wide repertoire of experiences as

well.

So, with machined pump components from PUMPSENSE,

you can be assured of precision engineering that is both cost-effective and that ensures the shortest delivery time in We have received and successfully executed orders from major pump companies, including those from the USA, Europe and Australia. |

| Pattern Making | |

Capability to translate drawings of complex pump components into patterns which will ensure high-quality castings. Highly skilled pattern makers with years of experience in developing casing and impeller patterns for international pump companies. Pattern making experience covers a whole range of centrifugal pumps from 1" to 64". Over 35 years of experience in this activity. Patterns developed for over 500 different sizes of pumps covering 15 basic types. |

|

| Foundry Resources | |

Dedicated engineers for foundry services with expertise and systems developed in the areas of mould making, method, quality surveillance, metallurgical control,etc. Partnership with

specialised cast iron and ductile iron foundries. Foundry team Partnership with specialist

stainless steel and bronze foundries for impeller On an average, over 1000 tons of pump castings processed annually. |

|

| Machining Resources | |

|

Well established machining procedure for the majority of the pump components, specialised skills developed over the past 35 years in the machining of components of centrifugal pumps. Specialised skills in the development of tools, jigs and fixtures required for accurate machining of pump components. |

| Optimum Hydraulic Performance | |

Documented experiences derived from a detailed study of pumps, hydraulic behaviour as a function of pattern making, methoding, dimensional accuracy of castings, surface finish, machining tolerances amongst other factors. Hydraulic performance variables include efficiency, recirculation and NPSH performance, closed valve behaviour, hydraulically generated axial and radial forces and repeatability of hydraulic performance. Manufacturing operations are based on the above ability to ensure optimum and repeatable performances. This is achieved through accurate pattern making, best foundry processes and accurate machining using appropriate gauges, jigs and fixtures . |

|

| Quality Assurance | |

The Quality Assurance System is certified by DNV. Pump components are routinely surveyed by independent agencies such as Lloyds, Bureau Veritus, ABS and others. Fully equipped to carry out hydrostatic pressure test, dynamic balancing, destructive and non-destructive tests in accordance with international standards. QA plan is discussed with the customer and full QA documentation including dimensional conformance report is provided. |

|